Deutsch: Planen-Durchführen-Prüfen-Handeln / Español: Planificar-Hacer-Verificar-Actuar / Português: Planejar-Fazer-Checar-Agir / Français: Planifier-Faire-Vérifier-Agir / Italiano: Pianificare-Fare-Verificare-Agire

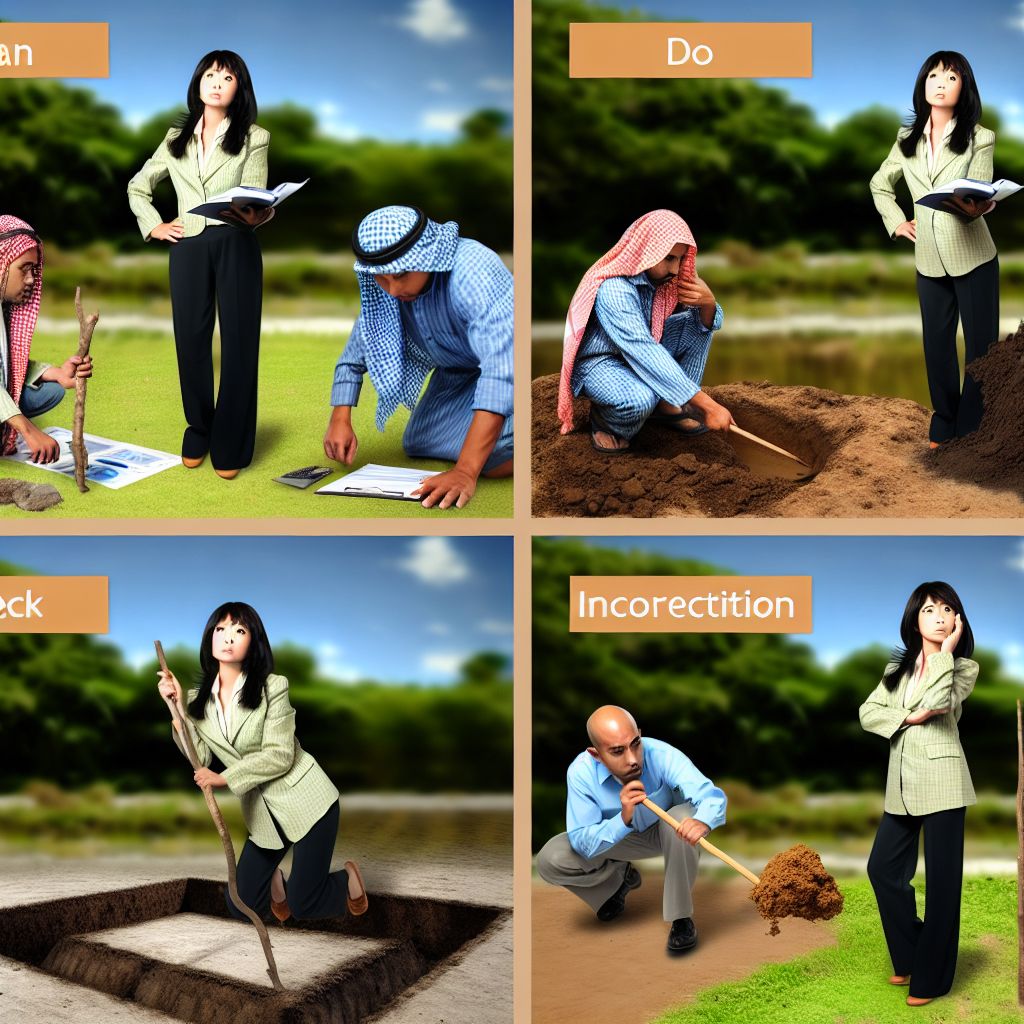

Plan-Do-Check-Act (PDCA) in the quality management context refers to a iterative four-step management method used for the control and continuous improvement of processes and products. It is a fundamental part of Total Quality Management (TQM) and is integral to the ISO 9001 Quality Management System standard. The PDCA cycle is designed to ensure that processes are efficiently planned, implemented, monitored, and improved over time.

Description

The PDCA cycle involves the following steps:

- Plan: Identify an opportunity and plan for change. Define objectives, processes, and resources needed to deliver results in accordance with the expected output.

- Do: Implement the plan on a small scale first to test the potential effects of the change.

- Check: Monitor and evaluate the outcomes of the 'Do' phase against the expected results to identify any discrepancies.

- Act: Take action based on what was learned in the 'Check' phase. If the change was successful, implement it on a wider scale and continuously assess your results. If the change did not work, begin the cycle again with a different plan.

Application Areas

The PDCA cycle can be applied to any area of an organization needing improvement, including:

- Product Development: For designing, testing, and refining new products.

- Process Improvement: To enhance efficiency and effectiveness of operational processes.

- Quality Control and Assurance: In establishing, implementing, and improving quality management systems.

- Environmental Management: For the continuous improvement of environmental performance.

Well-Known Examples

- Manufacturing Efficiency Improvements: Using PDCA to streamline production processes, resulting in reduced waste and increased productivity.

- Customer Service Enhancements: Applying PDCA to improve response times and customer satisfaction metrics.

Treatment and Risks

The successful application of PDCA requires careful planning and a commitment to continuous improvement. Potential risks include resistance to change, inadequate planning, or insufficient analysis during the 'Check' phase. These can be mitigated by:

- Engaging Stakeholders: Involving employees and other stakeholders in the planning and execution phases to ensure buy-in and facilitate the successful implementation of changes.

- Thorough Analysis: Ensuring that data collected during the 'Check' phase is accurately analyzed to inform effective actions.

- Iterative Approach: Recognizing that PDCA is an ongoing process, with each cycle building on the lessons learned from the previous one.

Examples of Sentences

- "The Plan-Do-Check-Act cycle is a cornerstone of quality management, providing a systematic framework for achieving continual improvement in processes and products."

- "By rigorously applying the PDCA cycle, organizations can foster a culture of quality and continuous improvement, driving operational excellence and customer satisfaction."

Similar Terms or Synonyms

- Deming Cycle

- Continuous Improvement Process

Summary

Plan-Do-Check-Act (PDCA) is a versatile and powerful approach in the quality management context for driving continuous improvement in organizations. By systematically planning, implementing, evaluating, and adjusting processes, companies can enhance their operational efficiency, product quality, and customer satisfaction. PDCA encourages a culture of proactive problem-solving and adaptability, which are essential for maintaining competitive advantage in today's fast-paced business environment.

--

Related Articles to the term 'Plan-Do-Check-Act' | |

| 'Quality management' at top500.de | ■■■■■■■■■■ |

| Quality management is a systematic approach to ensuring that an organisation's products and services . . . Read More | |

| 'Fragmentation' at psychology-lexicon.com | ■■■■■■■■ |

| Fragmentation in the psychology context refers to the Disintegration or breakdown of an individual's . . . Read More | |

| 'Calibration' at top500.de | ■■■■■■■■ |

| Calibration in the industrial context refers to the process of adjusting and verifying the Accuracy of . . . Read More | |

| 'Validation' | ■■■■■■■■ |

| Validation in the quality management context refers to the process of confirming that a product, service, . . . Read More | |

| 'Audit' at top500.de | ■■■■■■■ |

| Audit in the industrial or industry context refers to a systematic Examination of a company’s accounts, . . . Read More | |

| 'Compatibility' at psychology-lexicon.com | ■■■■■■ |

| In the psychology context, compatibility refers to the degree to which two individuals are able to coexist . . . Read More | |

| 'Control' | ■■■■■■ |

| In the context of quality management, Control refers to the systematic and continuous process of monitoring, . . . Read More | |

| 'Strain' at psychology-lexicon.com | ■■■■■■ |

| Strain in psychology refers to the mental, emotional, or physical Stress experienced by an individual . . . Read More | |

| 'Setup' | ■■■■■ |

| Setup in the quality management context refers to the preparation, configuration, or organisation of . . . Read More | |

| 'Check' at top500.de | ■■■■ |

| Check in the context industrial environment refers to the process of evaluating and verifying that activities, . . . Read More | |