Deutsch: Filtration / Español: Filtración / Português: Filtração / Français: Filtration / Italiano: Filtrazione

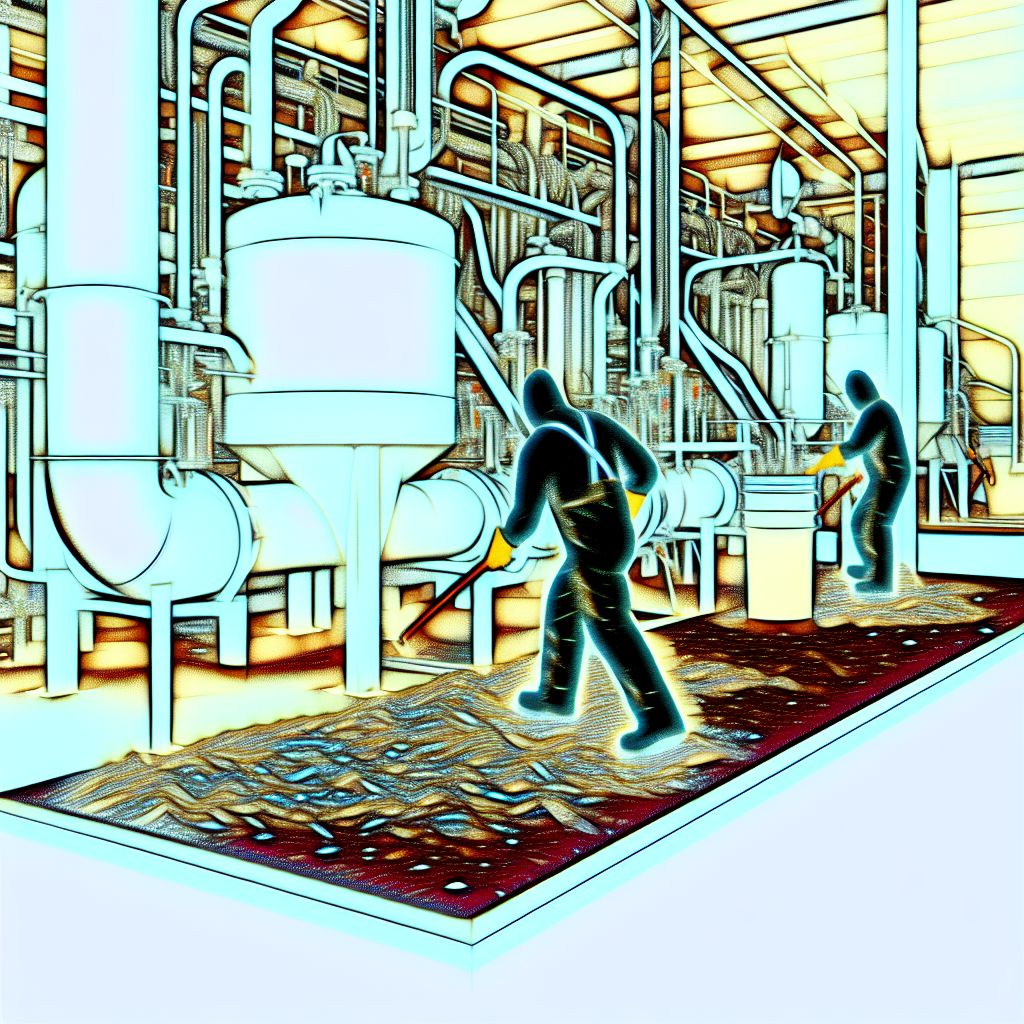

Filtration in the context of quality management refers to the process or technique used to separate unwanted materials or impurities from products, substances, or environments to ensure they meet specified quality standards. It's a critical operation in many industries where purity, cleanliness, and compliance with health and safety standards are paramount. Filtration can involve the use of physical barriers, chemical processes, or biological agents to remove solids, liquids, or gases from a medium, ensuring the final product's or environment's quality and safety.

Description

In quality management, filtration is employed as a means of quality control and assurance, integral to maintaining product integrity, protecting equipment, and ensuring a clean manufacturing environment. The process is designed to meet regulatory requirements, industry standards, and customer expectations. Effective filtration contributes to product consistency, process reliability, and overall operational efficiency.

Application Areas

Filtration is applied across various aspects of quality management in industries such as:

- Pharmaceuticals and Healthcare: Sterilizing liquids and gases used in manufacturing processes and patient care settings to remove contaminants and prevent infections.

- Food and Beverage: Ensuring the safety and quality of products by removing particulate matter and microorganisms from ingredients and processing environments.

- Water Treatment: Purifying water for industrial use or consumption by removing harmful substances and pathogens.

- Manufacturing: Protecting machinery and products from contamination by filtering air and fluids within production facilities.

- Air Quality Management: Maintaining clean air in manufacturing and office environments to protect employee health and sensitive equipment.

Well-Known Examples

An example of filtration in quality management can be found in the semiconductor manufacturing industry, where ultra-pure water is essential for cleaning silicon wafers. Any impurities can interfere with the microfabrication process of semiconductors. Filtration systems are used to remove these impurities, ensuring the water meets the stringent purity standards required for this process.

Treatment and Risks

The absence of effective filtration processes can lead to product contamination, increased waste, equipment damage, and non-compliance with regulatory standards, posing significant risks to public health and safety. To mitigate these risks, it is crucial to design and maintain filtration systems appropriately, conduct regular performance monitoring, and ensure filters are replaced or cleaned as required to maintain effectiveness.

Similar Terms or Synonyms

In the context of quality management, related terms to filtration include purification, separation, and clarification.

Weblinks

- environment-database.eu: 'Filtration' in the glossary of the environment-database.eu

- top500.de: 'Filtration' in the glossary of the top500.de

- umweltdatenbank.de: 'Filtration' im Lexikon der umweltdatenbank.de (German)

Summary

Filtration in quality management is a vital process for removing unwanted materials or impurities to achieve and maintain high-quality standards in products, processes, and environments. By implementing effective filtration techniques, organizations can ensure product safety, regulatory compliance, and customer satisfaction across various industries.

--

Related Articles to the term 'Filtration' | |

| 'Filtration' at top500.de | ■■■ |

| Filtration in the industrial and industry context refers to the process of separating solids from liquids . . . Read More | |