Deutsch: Kalibrieren / Español: Calibración / Português: Calibração / Français: Étalonnage / Italiano: Taratura /

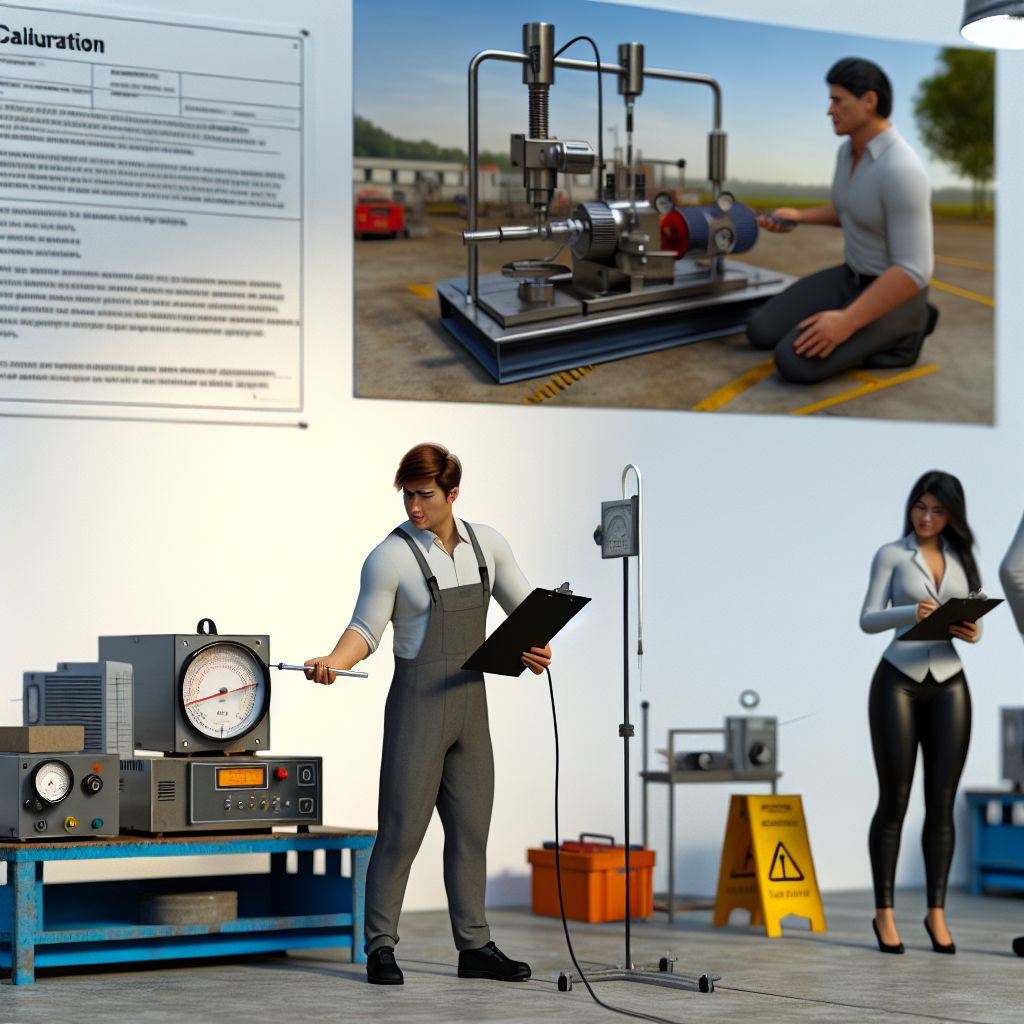

Calibrating in the quality management context refers to the process of adjusting, verifying, or fine-tuning measuring instruments, equipment, or devices to ensure they provide accurate and reliable measurements. Calibration is essential in various industries to maintain the precision and consistency of instruments used for quality control, testing, and research. It involves comparing the measurement output of a device to a known reference standard and making necessary adjustments to minimize measurement errors.

Application Areas

- Manufacturing: In manufacturing, calibration is crucial for maintaining the accuracy of equipment such as weighing scales, thermometers, and pressure gauges used in production processes.

- Laboratory Testing: Laboratories calibrate instruments like spectrophotometers, chromatographs, and pH meters to ensure the accuracy of analytical results.

- Healthcare: Medical devices such as blood pressure monitors and thermometers require regular calibration to provide accurate patient measurements.

- Aerospace: Aircraft and spacecraft instruments, such as altimeters and gyroscopes, undergo calibration to ensure safe and precise navigation.

- Automotive: Calibration is performed on sensors and diagnostic equipment used in vehicle manufacturing and maintenance.

Examples

- A laboratory technician is calibrating a pipette to ensure accurate volume measurements.

- An automotive technician calibrates the sensors in a vehicle's advanced driver-assistance system for optimal performance.

- A manufacturing plant schedules routine calibration of temperature sensors to maintain product quality.

Risks

- Failure to calibrate measuring instruments can lead to inaccurate data, potentially causing product defects, safety hazards, or compliance issues.

- Inadequate calibration practices may result in financial losses due to rework, waste, or product recalls.

History and Legal Basics

Calibration has a long history dating back to ancient civilizations that used standardized units of measurement. Today, various international standards and regulations, such as ISO 17025, govern calibration practices. These standards outline requirements for calibration laboratories, ensuring the traceability of measurements to recognized standards.

Examples of Sentences

- The technician is responsible for calibrating all the pressure gauges in the facility.

- Before conducting the experiment, the scientist meticulously performed the calibration of the spectrophotometer.

- The laboratory's calibrated equipment guarantees the accuracy of its test results.

- The company invests in regular calibrations to maintain the precision of its measurement tools.

Similar Terms

Weblinks

- industrie-lexikon.de: 'Kalibrieren' in the industrie-lexikon.de (German)

- top500.de: 'Calibrating' in the glossary of the top500.de

Summary

calibrating is a fundamental process in quality management that ensures the reliability and accuracy of measuring instruments and equipment across various industries. By regularly calibrating devices, organizations can trust the data they generate, leading to improved product quality, safety, and compliance with industry standards.

Related Articles to the term 'Calibrating' | |

| 'Trimmer' | ■■■■■■■■■■ |

| In the quality management context, a trimmer refers to a device or instrument used for the precise adjustment . . . Read More | |

| 'Measuring equipment' | ■■■■■■■■■■ |

| Measuring equipment refers to the tools and instruments used to measure various parameters with precision . . . Read More | |

| 'Measurement accuracy' | ■■■■ |

| Measurement accuracy is a critical concept in quality management, ensuring that measurements conform . . . Read More | |

| 'Qualification' | ■■■ |

| Qualification in the context of quality management refers to a systematic process of evaluating, assessing, . . . Read More | |

| 'Accuracy' | ■■ |

| In the context of quality management, \'accuracy\' refers to the degree of conformity or correctness . . . Read More | |

| 'Control' | ■■ |

| In the context of quality management, Control refers to the systematic and continuous process of monitoring, . . . Read More | |

| 'Straightness' | ■■ |

| Straightness in the quality management context refers to the degree to which an object or line conforms . . . Read More | |

| 'Sensitivity' | ■■ |

| Sensitivity in the quality management context refers to the ability of a system, process, or instrument . . . Read More | |

| 'Welder' | ■ |

| In the quality management context, a welder refers to a skilled professional responsible for joining . . . Read More | |

| 'Examination' | ■ |

| Examination in the quality management context refers to the systematic inspection, analysis, and evaluation . . . Read More | |